Page 175 - Bürkert

P. 175

On-Off Pneumatically Operated 2/2-way Angle Valve for Liquids

2000 G 1/2” - G 2 1/2”

• Waterhammer-free

• High flow rates

• Self adjusting double packing 2 (A)

• Optical position indicator is standard

1 (P)

• Rotating power head to orient air

control connections 4 (B)

1 (P)

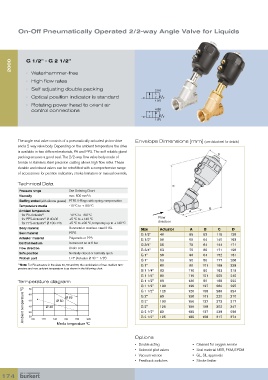

The angle seat valve consists of a pneumatically actuated piston-drive Envelope Dimensions [mm] (see datasheet for details)

and a 2-way valve body. Depending on the ambient temperature the drive

is available in two different materials, PA and PPS. The self reliable gland

packing ensures a good seal. The 2/2-way flow valve body made of

bronze or stainless steel precision casting allows high flow rates. These

durable and robust valves can be retrofitted with a comprehensive range

of accessories for position indication, stroke limitation or manual override.

Technical Data

Pressure range See Ordering Chart

Viscosity max. 600 mm /s

2

Stuffing socket (with silicone grease) PTFE V-Rings with spring compensation

Temperature media -10 ºC to +180 ºC

Ambient temperature

for PA-Actuator 1) -10 ºC to +60 ºC

1)

for PPS-Actuator Ø 40-80 +5 ºC to +140 ºC Flow

for PPS-Actuator Ø 100-125 +5 ºC to +90 ºC, temporary up to +140 ºC direction

1)

Body material Gunmetal or stainless steel 316L Size Actuator A B C D

Seal material PTFE G 1/2” 40 65 53 115 139

Actuator material Polyamide or PPS G 1/2” 50 65 64 140 163

Control medium Instrument air at 6 bar G 3/4” 50 75 64 144 171

Flow direction Under seat G 3/4” 63 75 80 171 198

Safe position Normally closed or normally open

G 1” 50 90 64 152 181

Pilot air port 1/4” (Actuator Ø 40 = 1/8”)

G 1” 63 90 80 177 206

1) Note: For PA actuators in the sizes 40, 50 and 63, the combination of max. medium tem- G 1” 80 90 101 198 228

perature and max. ambient temperature is as shown in the following chart

G 1 1/4” 63 110 80 183 219

G 1 1/4” 80 110 101 205 240

Temperature diagram G 1 1/2” 63 120 80 188 222

G 1 1/2” 100 120 127 260 295

Ambient temperature °C 50 100 120 Ø 40 140 Ø 50 160 180 200 G 2” 80 150 101 225 270

70

289

120

125

G 1 1/2”

324

158

60

Ø 63

100

150

272

G 2”

127

317

125

150

302

347

G 2”

158

40

127

185

239

80

G 2 1/2”

296

30

158

374

317

185

125

G 2 1/2”

20

Media temperature °C

Options

• Double acting • Cleaned for oxygen service

• Solenoid pilot valves • Seal material NBR, FKM, EPDM

• Vacuum version • GL, SIL approvals

• Feedback switches • Stroke limiter

174