Page 357 - Bürkert

P. 357

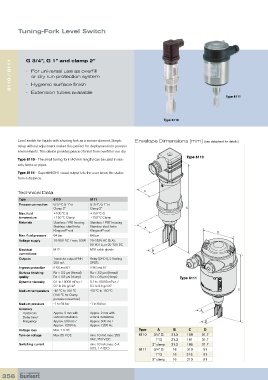

Tuning-Fork Level Switch

8110 / 8111 G 3/4”, G 1” and clamp 2”

• For universal use as overfill

or dry run protection system

• Hygienic surface finish

• Extension tubes available

Type 8111

Type 8110

Level switch for liquids with a tuning fork as a sensor element. Simple Envelope Dimensions [mm] (see datasheet for details)

setup without adjustment makes this perfect for deployment into process

environments. This device provides peace of mind from overfill or run dry

Type 8110

Type 8110 - The small tuning fork (40 mm length) can be used in ves-

sels, tanks or pipes.

Type 8111 - SuperBRIGHT visual output lets the user know the status

from a distance.

Technical Data D

Type 8110 8111

Process connection G 3/4”, G 1” or G 3/4”, G 1” or

Clamp 2” Clamp 2” C

Max. fluid +100 ºC G +150 ºC G

temperature +150 ºC Clamp +150 ºC Clamp

Materials Stainless / PEI housing Stainless / PBT housing

Stainless steel forks Stainless steel forks A

®

®

Klingersil seal Klingersil seal D

Max. fluid pressure 64 bar 64 bar

Voltage supply 10-55V DC / max. 0.5W 20-253V AC (5 A),

50-60 Hz, or 20-72V DC

Electrical M12 M20 cable glands B

connections

Outputs Transistor output PNP, Relay (DPDT), 2 floating

250 mA SPDTs

Ingress protection IP66 and 67 IP66 and 67

Surface finishing Ra < 3.2 µm (thread) Ra < 3.2 µm (thread)

quality Ra < 0.8 µm (clamp) Ra < 0.8 µm (clamp) Type 8111

Dynamic viscosity 0.1 to 10000 mPa.s / 0.1 to 10000 mPa.s /

0.7 to 2.5 g/cm 3 0.7 to 2.5 g/cm 3

Medium temperature -40 °C to 100 °C -50 °C to 150 °C C

(150 °C for Clamp

process connection)

Medium pressure -1 to 64 bar -1 to 64 bar

Accuracy A

Hysteresis Approx. 2 mm with Approx. 2 mm with

Delay time/ vertical installation vertical installation

Frequency Approx. 500 ms / Approx. 500 ms / B

Approx. 1200 Hz Approx. 1200 Hz

Voltage loss Max. 1 V DC Type A B C D

Turn-on voltage Max. 55 V DC min.: 10 mV; max.: 253 8110 3/4” G 21.3 158 31.7

VAC, 253 V DC 1” G 21.3 161 31.7

Switching current min.: 10 mA; max.: 5 A 2” clamp 21.3 165 31.7

(AC), 1 A (DC) 8111 3/4” G 16 210 91

1” G 16 213. 91

2” clamp 16 213 91

356