Page 359 - Bürkert

P. 359

Vibrating Level Switch

8112

• For universal use as overfill or dry run

protection system

• Setup without adjustment

• For food and beverage industry thanks

to surface finishing < 0.8 μm

• ATEX approvals

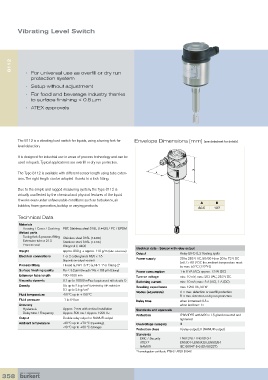

The 8112 is a vibrating level switch for liquids, using a tuning fork for Envelope Dimensions [mm] (see datasheet for details)

level detection.

It is designed for industrial use in areas of process technology and can be

used in liquids. Typical applications are overfill or dry run protection.

B

The Type 8112 is available with different sensor length using tube exten- A

sion. The right length can be adapted thanks to a lock fitting.

Due to the simple and rugged measuring system, the Type 8112 is

virtually unaffected by the chemical and physical features of the liquid.

It works even under unfavourable conditions such as turbulence, air

A B

bubbles, foam generation, buildup or varying products.

80.5 127

Technical Data

Materials

Housing / Cover / Seal ring PBT, Stainless steel 316L (1.4435) / PC / EPDM

Wetted parts

Tuning fork & process fitting Stainless steel 316L (1.4435)

Extension tube ø 21.3 Stainless steel 316L (1.4435)

Process seal Klingersil C 4400

Electrical data - Sensor with relay output

Weight approx. 890 g + approx. 110 g/m (tube extension) Output Relay (DPDT), 2 floating spdts

Electrical connections 1 or 2 cable glands M20 x 1.5

(depends on output version) Power supply 20 to 253 V AC, 50/60 Hz or 20 to 72 V DC

(at U > 60 V DC the ambient temperature must

Process fitting Thread G, NPT 3/4”, G, NPT 1” or Clamp 2” be max. 50 °C (122°F))

Surface finishing quality Ra < 3.2 μm (thread) / Ra < 0.8 μm (Clamp) Power consumption 1 to 8 VA (AC); approx. 1.3 W (DC)

Extension tube length 200-1000 mm Turn-on voltage min.: 10 mV; max.: 253 VAC, 253 V DC

Viscosity dynamic 0.1 up to 10000 mPa.s (requirement: with density 1) Switching current min.: 10 mA; max.: 5 A (AC), 1 A (DC)

Density 0.5 up to 2.5 g/cm (selected by DIP switch) or Breaking capacitance max. 1250 VA, 50 W

3

0.7 up to 2.5 g/cm 3 Modes (adjustable) A = max. detection or overfill protection

Fluid temperature -50 ºC up to +150 ºC B = min. detection or dry run protection

Fluid pressure -1 to 64 bar Delay time when immersed: 0.5 s

Accuracy when laid bare: 1s

Hysteresis Approx. 2 mm with vertical installation Standards and approvals

Delay time / Frequency Approx. 500 ms / Approx. 1200 Hz Protection IP66/IP67 with M20 x 1.5 gland mounted and

Output Double relay output or NAMUR output tightened

Ambient temperature -40 ºC up to +70 ºC (Operating); Overvoltage category III

-40 ºC up to +80 ºC (Storage)

Protection class I (relay output); II (NAMUR output)

Standards

EMC / Security EN61326 / EN61010-1

ATEX 1) EN50014; EN50020; EN50284

NAMUR IEC 60947-5-6 (EN 50227)

1) homologation certificate PTB 07 ATEX 2004X

358