Page 85 - Bürkert

P. 85

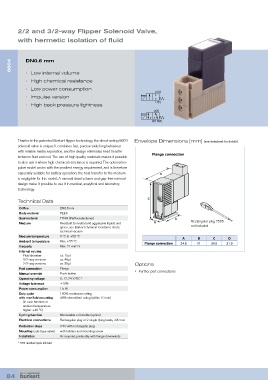

2/2 and 3/2-way Flipper Solenoid Valve,

with hermetic isolation of fluid

6604 DN0.6 mm

• Low internal volume

• High chemical resistance

• Low power consumption

2 (A)

• Impulse version

1 (P)

• High back pressure tightness

2(A)

1(P) 3(R)

Thanks to the patented Bürkert flipper technology, the direct-acting 6604 Envelope Dimensions [mm] (see datasheet for details)

solenoid valve is unique. It combines fast, precise switching behaviour

with reliable media separation, and the design eliminates heat transfer Flange connection

between fluid and coil. The use of high quality materials makes it possible

to also use it where high chemical resistance is required. The optional im-

pulse model works with the smallest energy requirement, and is therefore

especially suitable for battery operation; the heat transfer to the medium D

is negligible for this model. A minimal dead volume and gap-free internal

design make it possible to use it in medical, analytical and laboratory

technology.

C

Technical Data

Orifice DN0.6 mm

Body material PEEK

Seal material FFKM (Perfluorelastomer) A

Medium Resistant to neutral and aggressive liquids and B Rectangular plug 2505

gases, see Bürkert chemical resistance chart; not included

technical vacuum

Medium temperature 0 °C to +50 °C A B C D

Ambient temperature Max. +55 °C Flange connection 24.8 11 29.5 31.9

Viscosity Max. 21 mm /s

2

Internal volume

Fluid chamber ca. 15µl

3/2-way versions ca. 45µl

2/2-way versions ca. 35µl Options

Port connection Flange

Manual override Push-button • Further port connections

Operating voltage 6, 12, 24 V/DC *

Voltage tolerance ±10%

Power consumption 1.5 W

Duty cycle 100% continuous rating

with manifold mounting 40% intermittent rating (within 10 min)

(in case Medium or

ambient temperature

higher +40 °C)

Cycling function Monostable or bistable (option)

Electrical connections Rectangular plug or 2 single flying leads, 300 mm

Protection class IP40 with rectangular plug

Mounting (sub-base valve) with holders and mounting screw

Installation As required, preferably with flange downwards

* 10% residual ripple allowed

84