Page 137 - Bürkert

P. 137

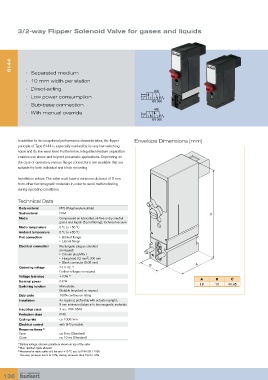

3/2-way Flipper Solenoid Valve for gases and liquids

6144

• Separated medium

• 10 mm width per station

• Direct-acting

2(A)

• Low power consumption

1(P) 3(R)

• Sub-base connection

4(B)

• With manual override

1(P) 3(R)

In addition to its exceptional performance characteristics, the flipper Envelope Dimensions [mm]

principle of Type 6144 is especially marked by its very low switching

noise and its low wear level. Furthermore, integrated medium separation

enables use above and beyond pneumatic applications. Depending on

the case of operation, various flange connections are available that are

suitable for both individual and block mounting.

Installation advice: The valve must have a minimum distance of 5 mm

from other ferromagnetic materials in order to avoid malfunctioning

during operating conditions.

Technical Data

Body material PPS (Polyphenylensulfide)

Seal material FKM C

Media Compressed air lubricated, oil-free or dry; neutral

gases and liquids (5 µm filtering); technical vacuum

Media temperature 0 °C to +55 °C

Ambient temperature 0 °C to +55 °C

Port connection • Bürkert flange

• Lateral flange

Electrical connection Rectangular plug as standard

on request:

• Circular plug M8x1

2

• Flying lead 0.2 mm , 300 mm

• Blank connector (5.08 mm) A

Operating voltage 24 V DC 1) B

Further voltages on request

Voltage tolerance ±10%

2)

Nominal power 0.8 W A B C

Switching function Monostable 18 10 41.45

Bistable (impulse) on request

Duty cycle 100% continuous rating

Installation As required, preferably with actuator upright;

5 mm minimum distance to ferromagnetic materials

Insulation class 3 acc. VDE 0580

Protection class IP40

Cycling rate ca. 1000/min

Electrical control with SPS possible

Response times 3)

Open ca. 8 ms (Standard)

Close ca. 10 ms (Standard)

1) Battery voltage; observe polarity as shown on top of the valve

2) Max. residual ripple allowed

3) Measured at valve outlet at 6 bar and +20 °C acc. to DIN ISO 12238

Opening: pressure rise 0 to 10%, closing: pressure drop 100 to 10%

136