Page 289 - Bürkert

P. 289

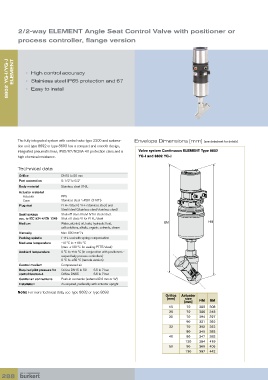

2/2-way ELEMENT Angle Seat Control Valve with positioner or

process controller, flange version

8802 YG-I/YG-J ELEMENT • High control accuracy

• Stainless steel IP65 protection and 67

• Easy to install

The fully integrated system with control valve type 2300 and automa- Envelope Dimensions [mm] (see datasheet for details)

tion unit type 8692 or type 8693 has a compact and smooth design,

integrated pneumatic lines, IP65/67/NEMA 4X protection class and a Valve system Continuous ELEMENT Type 8802

high chemical resistance. YG-I and 8802 YG-J

Technical data

Orifice DN15 to 50 mm

Port connection G 1/2” to G 2”

Body material Stainless steel 316L

Actuator material

Actuator PPS

Case Stainless steel 1.4561 (316Ti)

Plug seal PTFE/Steel (PTFE/stainless steel) and

Steel/steel (Stainless steel/stainless steel)

Seat leakage Shut-off class III and IV for steel/steel.

acc. to IEC 534-4/EN 1349 Shut-off class VI for PTFE/steel

Medium Water, alcohol, oil, fuels, hydraulic fluid, BM HM

salt solutions, alkalis, organic solvents, steam

Viscosity Max. 600 mm /s

2

Packing spindle PTFE seal with spring compensation

Mediums temperature -10 °C to +185 °C

(max. +130 °C for sealing PTFE/steel)

Ambient temperature 0 °C to +55 °C (in conjunction with positioners -

respectively process controllers)

0 °C to +80 °C (remote version)

Control medium Compressed air

Required pilot pressure for Orifice DN15 to 50 5.5 to 7 bar

control function A Orifice DN65 5.6 to 7 bar

Control air connections Push-in connector (external Ø 6 mm or ¼”)

Installation As required, preferably with actuator upright

Note: For more technical data, see Type 8692 or Type 8693

Orifice Actuator

[mm] size

[mm] HM BM

15 70 280 308

20 70 288 318

25 70 294 327

90 331 362

32 70 302 342

90 345 382

40 90 347 383

130 384 419

50 90 360 406

130 397 442

288