Page 217 - Bürkert

P. 217

Manually Operated 2/2-way Forged Diaphragm Valve

3233 DN8-80 mm

• Hermetic separation of fluids

from actuator

• For high purity and aseptic mediums

• Certifications for hygienic processing

applications

• CIP/SIP

• Zero dead volume

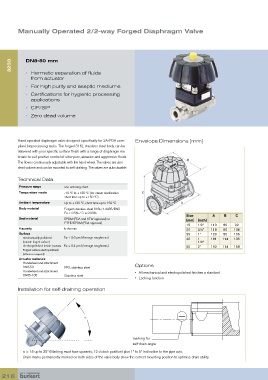

Hand operated diaphragm valve designed specifically for 3A/FDA com- Envelope Dimensions [mm]

pliant bioprocessing tasks. The forged 316L stainless steel body can be

delivered with your specific surface finish with a range of diaphragm ma-

terials to suit positive control of ultra-pure, abrasive and aggressive fluids.

The flow is continuously adjustable with the hand wheel. The valves are zero

dead volume and can be mounted to self-draining. The valves are autoclavable.

Technical Data

Pressure range see ordering chart

Temperature media -10 ºC to +130 ºC (for steam sterilization

short time up to +150 °C)

Ambient temperature Up to +130 ºC, short time up to 150 ºC

Body material Forged stainless steel 316L/1.4435/BN2

Fe < 0.5% / C ≤ 0.03%

Size A B C

Seal material EPDM (FDA and KTW approval) or [mm] [inch]

PTFE/EPDM (FDA approval)

15 1/2” 110 80 92

Viscosity to viscous 20 3/4” 119 80 104

Surface 25 1” 129 80 106

mechanically polished Ra ≤ 0.6 µm (Average roughness) 40 1 161 114 135

(outside forged surface) 1/2”

electropolished inside (outside Ra ≤ 0.4 µm (Average roughness) 50 2” 192 114 158

Forged surface electropolished)

(others on request)

Actuator materials

Handwheel and attachment

DN8-50 PPS, stainless steel Options

Handwheel and attachment • All mechanical and electropolished finishes a standard

DN65-100 Stainless steel

• Locking function

Installation for self-draining operation

α

marking for

self-drain angle

α = 15 up to 35º (Marking must face upwards, 12 o’clock position) plus 1º to 5º inclination to the pipe axis.

Drain marks permanently marked on both sides of the valve body show the correct mounting position to optimise drain ability.

216