Page 418 - Bürkert

P. 418

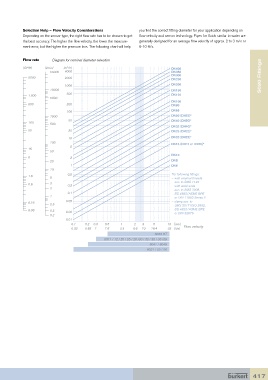

Selection Help – Flow Velocity Considerations you find the correct fitting diameter for your application depending on

Depending on the sensor type, the right flow rate has to be chosen to get flow velocity and sensor technology. Pipes for fluids similar to water are

the best accuracy. The higher the flow velocity, the lower the measure- generally designed for an average flow velocity of approx. 2 to 3 m/s or

ment error, but the higher the pressure loss. The following chart will help 6-10 ft/s.

Flow rate Diagram for nominal diameter selection

3

[GPM] [l/min] [m /h] DN400

55000 4000 DN350

DN300 S020 Fittings

8000 2000 DN250

1000 DN200

10000 DN150

500

1.600 DN125

5000

DN100

800 200 DN80

100 DN65

1000 DN50 (DN65)*

50 DN40 (DN50)*

160 500

DN32 (DN40)*

80 20 DN25 (DN32)*

10 DN20 (DN25)*

100 DN15 (DN15 or DN20)*

5

16

50

DN10

8 2

20 DN8

1 DN6

10

0.5 *for following fittings:

1.6

5 – with external threads

0.8 3 0.2 acc. to SMS 1145

– with weld-ends

2 acc. to SMS 3008,

0.1 BS 4825 | ASME BPE

1 or DIN 11850 Series 2

0.05 – clamp acc. to

0.16

0.5 SMS 3017 / ISO 2852,

0.08 0.3 0.02 BS 4825 / ASME BPE

0.2 or DIN 32676

0.01

0.1 0.2 0.3 0.5 1 2 3 5 10 [m/s]

0.33 0.65 1 1.6 3.3 6.6 10 16.4 33 [ft/s] Flow velocity

8030 HT

8011 / 12 / 20 / 25 / 26 /30 / 32 / 35 / 36 /39

8041 / 8045

8051 / 55 / 56

417