Page 428 - Bürkert

P. 428

Technical Data (Standard) Options

* For the 97/23/CE pressure directive, the device can only be used under following conditions • AS-i Connection

(dependent on max. pressure, pipe diameter and fluid).

• Hygienic clamp and ASME weld end connections

Type of fluid Conditions • ANSI flange connection

Fluid group 1, §1.3.a DN ≤ 25 only

DN ≤ 32 or • PVDF and PP fittings.

Fluid group 2, §1.3.a

DN > 32 and PN*DN ≤ 1000 • High flow fittings (8020) to DN350 mm

Fluid group 1, §1.3.b PN*DN ≤ 2000 • Various sealing materials SE30

Fluid group 2, §1.3.b DN ≤ 200 • Individual calibration certificate

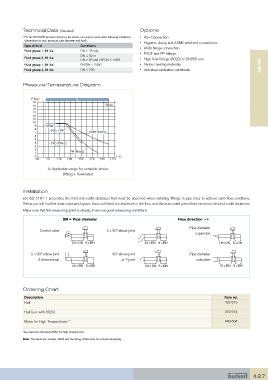

Pressure/Temperature Diagram

P (bar) A

16

15 Metal

14

13

12

11

10

9 PVDF

8 PVC + PP

7 PVDF (PN10)

6

5

4 PVC (PN10)

3

2 50 x DN 5 x DN

1 PP (PN10)

0 T °C

-30 -10 +10 +30 +50 +70 +90 +110

A: Application range for complete device

(fitting + flowmeter) 40 x DN 5 x DN

Installation

50 x DN 5 x DN 25 x DN 5 x DN

EN ISO 5167-1 prescribes the inlet and outlet distances that must be observed when installing fittings in pipe lines to achieve calm flow conditions.

Below you will find the most important layouts that could lead to turbulence in the flow, and the associated prescribed minimum inlet and outlet distances.

Make sure that the measuring point is steady, to ensure good measuring conditions

DN = Pipe diameter 40 x DN 5 x DN Flow direction --> 20 x DN 5 x DN

Pipe diameter

Control valve 2 x 90° elbow joint

expansion

50 x DN 5 x DN 25 x DN 5 x DN 18 x DN 5 x DN

2 x 90° elbow joint 90° elbow joint Pipe diameter

3 dimensional or T-joint reduction

40 x DN 5 x DN 20 x DN 5 x DN 15 x DN 5 x DN

Ordering Chart 25 x DN 5 x DN 18 x DN 5 x DN

Description Item no.

Hall 423 913

Hall (use with 8025) 20 x DN 5 x DN 15 x DN 5 x DN 423 914

Meter for High Temperatures * 449 694

*see separate datasheet 8030, for high temperatures

18 x DN 5 x DN

Note: The electronic module, SE30 and the fitting, S030 must be ordered separately

15 x DN 5 x DN

427